-

With ARM-based 32-bit SCM, highly integrated hardware, new reliability level.

-

480x272 LCD with backlight, multilingual interface (including English, Chinese or other languages) which can be chosen at the site, making commissioning convenient for factory personnel;

-

Improved LCD wear-resistance and scratch resistance due to hard screen acrylic;

-

Silicon panel and pushbuttons for better operation in high-temperature environment;

-

RS485 communication port enabling remote control, remote measuring, remote communication via ModBus protocol;

-

ETHERNET communication interface with multiple monitoring modes;

-

Micro SD port for recording of real-time operational data;

-

Equipped with SMS (Short Message Service) function. When genset is alarming, controller can send short messages via SMS automatically to max. 5 telephone numbers. besides, generator status can be controlled and checked using SMS;

-

Equipped with CANBUS port and can communicate with J1939 genset. Not only can you monitoring frequently-used data (such as water temperature, oil pressure, speed, fuel consumption and so on) of ECU machine, but also control starting up, shutdown , raising speed and speed droop via CANBUS port.

-

Suitable for 3-phase 4-wire, 3-phase 3-wire, single phase 2-wire, and 2-phase 3-wire systems with voltage 120/240V and frequency 50/60Hz;

-

Collects and shows 3-phase voltage, current, power parameter and frequency of generator or mains.

-

For Mains, controller has over and under voltage, over and under frequency, loss of phase and phase sequence wrong detection functions; For generator, controller has over and under voltage, over and under frequency, loss of phase, phase sequence wrong, over and reverse power, over current functions;

-

3 fixed analog sensors (temperature, oil pressure and liquid level);

-

2 configurable sensors can be set as sensor of temperature, oil pressure or fuel level;

-

Precision measure and display parameters about Engine,

-

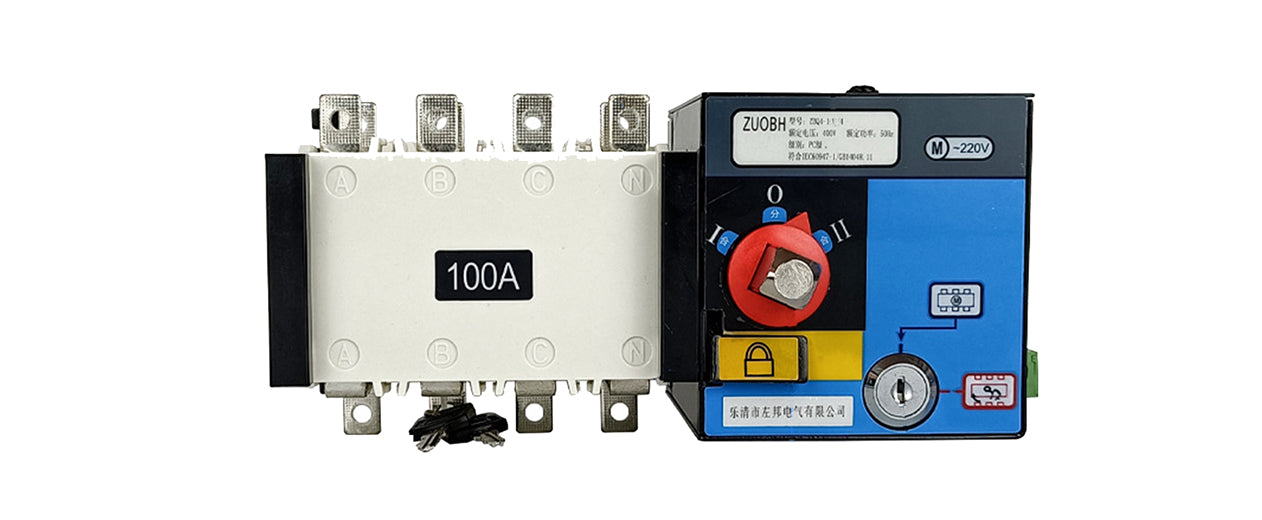

Protection: automatic start/stop of the gen-set, ATS(Auto Transfer Switch) control with perfect fault indication and protection function;

-

All output ports are relay-out;

-

Parameter setting: parameters can be modified and stored in internal EEPROM memory and cannot be lost even in case of power outage; most of them can be adjusted using front panel of the controller and all of them can be modified using PC via USB, RS485 or ETHERNET ports.

-

More kinds of curves of temperature, oil pressure, fuel level can be used directly and users can define the sensor curves by themselves;

-

Multiple crank disconnect conditions (speed sensor, oil pressure, generator frequency) are optional;

-

Widely power supply range DC(8~35)V, suitable to different starting battery voltage environment;

-

Event log, real-time clock, scheduled start & stop generator (can be set as start genset once a day/week/month whether with load or not);

-

Can be used on pumping units and as an indicating instrument (indicate and alarm are enable only, relay is inhibited );

-

Accumulative total run time and total electric energy of A and B. Users can reset it as 0 and re-accumulative the value which make convenience to users to count the total value as their wish.

-

Can control engine heater, cooler and fuel pump.

-

With maintenance function. Actions (warning, shutdown or trip and stop) can be set when maintenance time out;

-

All parameters used digital adjustment, instead of conventional analog modulation with normal potentiometer, more reliability and stability;

-

Waterproof security level IP55 due to rubber seal installed between the controller enclosure and panel fascia;

-

Metal fixing clips enable perfect in high temperature environment;

-

Modular design, anti-flaming ABS plastic enclosure, pluggable connection terminals and embedded installation way; compact structure with easy mounting.